Introducing the FlexFeeder, a groundbreaking solution designed to meet the evolving demands of electronics manufacturing. With the ability to seamlessly sort components ranging from 3 mm to 30 mm, the FlexFeeder eliminates the hassle of changing feeders for different parts, enhancing efficiency and flexibility in your automation system.

In today’s fast-paced manufacturing environment, the automation of electronics requires systems that can adapt to a variety of small parts with reliability and speed. The FlexFeeder is engineered to address these challenges, offering a versatile module that integrates effortlessly with industrial robots to perform applications such as sorting and assembly.

Versatile Compatibility:

The FlexFeeder can interface with both the IRC5 robot controller and any PLC controller, making it an adaptable choice for a wide range of automation setups.

Efficient Feeding Options:

Available in single and double variants, the FlexFeeder optimizes operational time by increasing the duration between refills. The larger unit is particularly effective for high-volume applications.

Enhanced Flexibility:

Its small internal gap design and integrated backlight options facilitate the feeding of various small parts, allowing for smooth transitions between different components without compromising efficiency.

Compact and Cost-Effective Design:

Both variants are designed to save installation space and reduce cycle times. The compact design allows for two or more feeders to operate side-by-side, eliminating the need for separate vision systems, thereby saving on both space and costs.

Robust Yet Quiet Operation:

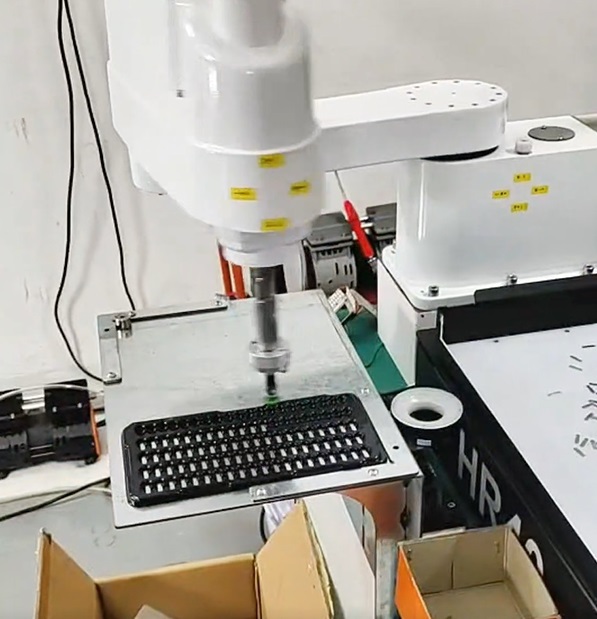

Powered by pneumatic cylinders, the FlexFeeder takes components from an unordered bulk supply and dispenses them in small, manageable quantities onto a flat pick surface visible to the vision system. The maintenance-free friction plates guide the cylinders silently, ensuring a smooth operation.

User-Friendly Integration:

The FlexFeeder features ground and rack mounting methods that simplify installation. Convenient handles make moving and lifting easier, while a user-friendly graphical interface (GUI) allows for one-click testing and real-time monitoring of production status.

Smart Sensors for Efficiency:

Equipped with intelligent sensors, the FlexFeeder can detect when the tank needs refilling and signal the operator. The tank can also be purged without power, enabling quick and safe part changes.

The FlexFeeder is not just an advanced feeding solution; it’s a critical component for any manufacturer looking to optimize their automation processes. With its exceptional flexibility, robust design, and user-friendly features, the FlexFeeder is poised to enhance your production capabilities while reducing costs and downtime. Embrace the future of small parts feeding and elevate your manufacturing efficiency with the FlexFeeder today!

Copyright © 2022-2024 LDT, inc. All rights reserved E-mail:[email protected]