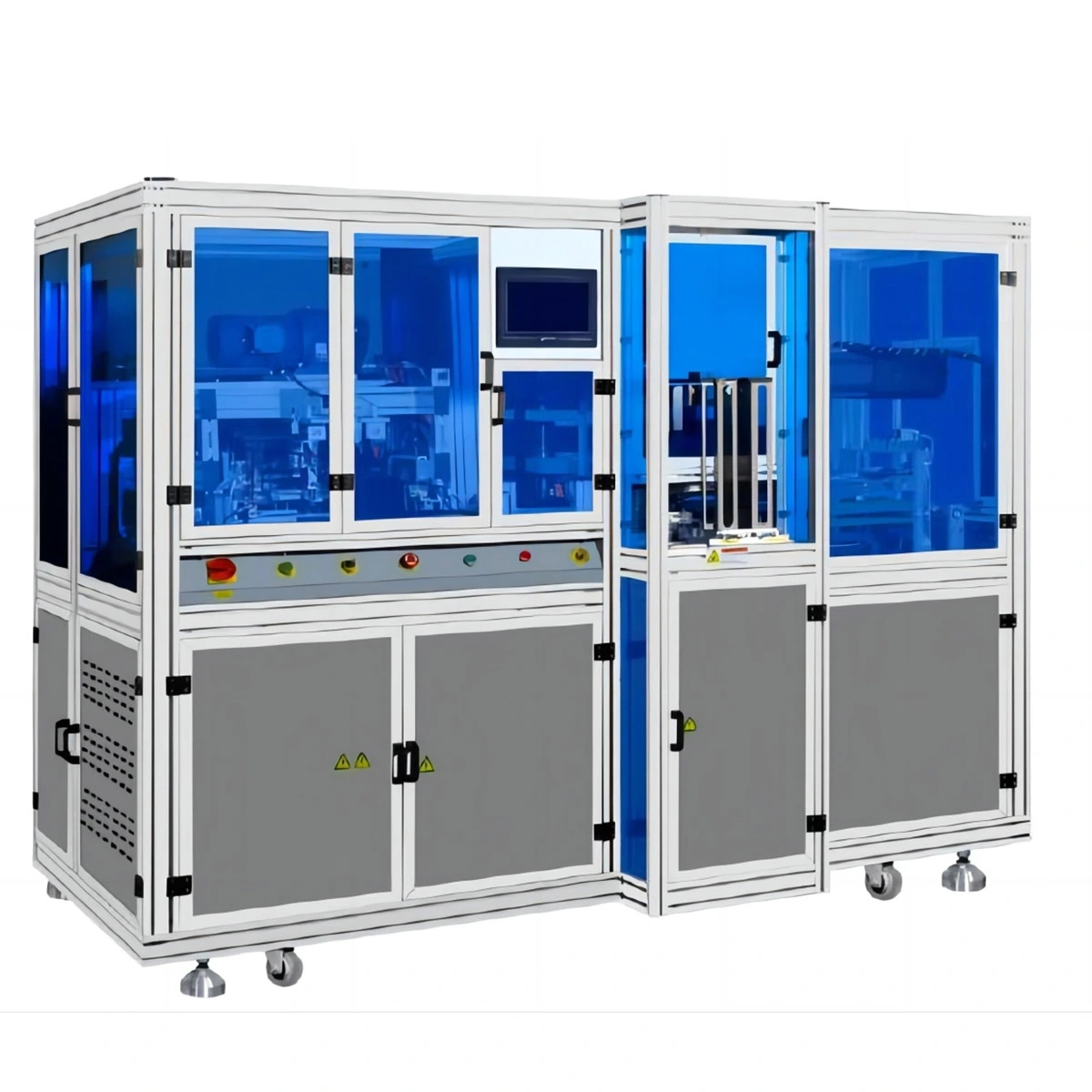

Model:LDT-ACP400

Features

This machine is an automatic all-in-one card punching equipment that adopts PLC control, incorporating with automatic feeding, sheet collating, sensor positioning, servo punching, card collecting, scrap pile up and collect functions. It’s specially suitable for bank card production.

① Machine do punching on ABS, PC cards (using special mold), which is the best cutting equipment for producing high-end special material cards.

② High sensitivity photoelectric sensor fits to imported servo system to feed material, each punching location parameter can be adjusted, high precision punching effect.

③ Adopt imported ball screw module and servo motor to step feeding materials, high accuracy and long operating life.

④ Big power, large torque servo as punching power, strong and fast. Product’s punching edge is more smooth.

⑤ Equipped with loading unit for big PVC sheet, easily & quickly to feed the materials. Automatic sheet loading unit, cooperates with collate copies construction to load the sheet quickly to the punching platform;

⑥ Collecting cards in sequence, allows the big sheet collected in sequence number, to meet the need of personalization card collection.

Double card boxes for switch over, each box has capacity of 500 standard cards. The boxes can be removed, easy to install the cards without stopping the machine.

Technical parameters

◎ Voltage: 380V 50HZ

◎ Power: 9.5KW

◎ Air source: over 6kg/cm2

◎ Gas consumption: 40L/min

◎ Layouts: 3*8, 4*8, 5*5 etc

◎ Control method: PLC+servo system

◎ Output: 18000-30000PCS

◎ Punching precision: ±0.03mm

◎ Materials: PVC, PET, PETG, paper card, mixed material.......

◎ Size: L2450*W1650*H1900mm

Copyright © 2022-2024 LDT, inc. All rights reserved E-mail:[email protected]