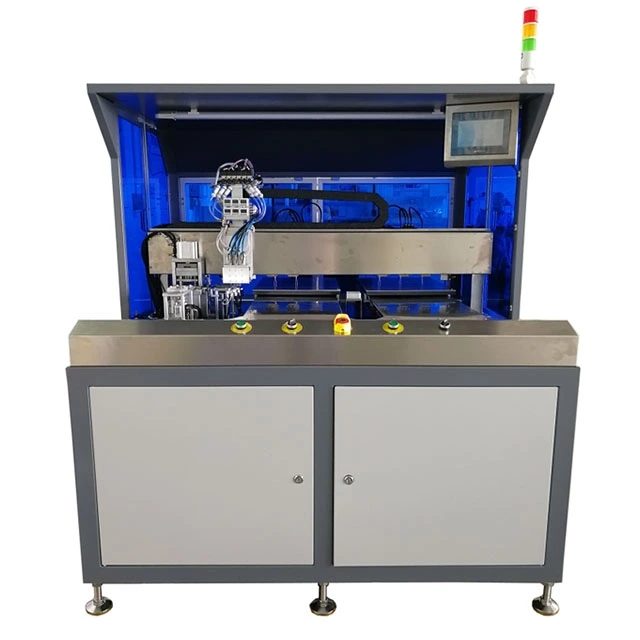

Functions and Features:

1. This machine is used for COB pick and placer with the tape format. First installing the roll tape on the machine, then the machine will punch the COB from the chips tape automatically.

2. The machine could pick 6 pieces of chips at one time, then place them on the sheets. It could improve the work efficiency and flexibility of the placing.

3. The 3*7 and 3*8 layouts are easily to make the changeover. The machine has both A and B platforms, and single chip with 3 axis (AY axis, BY axis, X axis) work mode. The COB placing parameters could be adjusted individually, which is easy to operate.

4. The machine has 6 units of glue dispensing devices. The glue dispensing group and pick & placer working group could work at the same time in different platforms. It could improve the work efficiency.

5. The machine is with the high accurate X-Y double axis, applying the servo system to realize the high precision position. Which could ensure the COB placing accuracy. The machine position accuracy is up to ±0.05mm.

6. The machine is equipped with many sets of sensors, and monitoring the working status. The machine will stop and alarm when the abnormal happens.

Parameters:

Power Source:AC 220V/50 HZ

Power: around 3.0KW

Air Pressure:6kg/cm2 (dry/no water)

Air Consumption:around 30L/min

Dimension:L1530×W1460×H1730mm

Weight:around 950Kg

Capacity:around 4000PCS/H

Servo Control Method:PLC Program + Servo System

Operator:1 Person

Material: The chips in Tape format;The PVC、ABS、PETG sheets are with chips’ holes.

Position Accuracy:±0.05mm

Copyright © 2022-2024 LDT, inc. All rights reserved E-mail:[email protected]