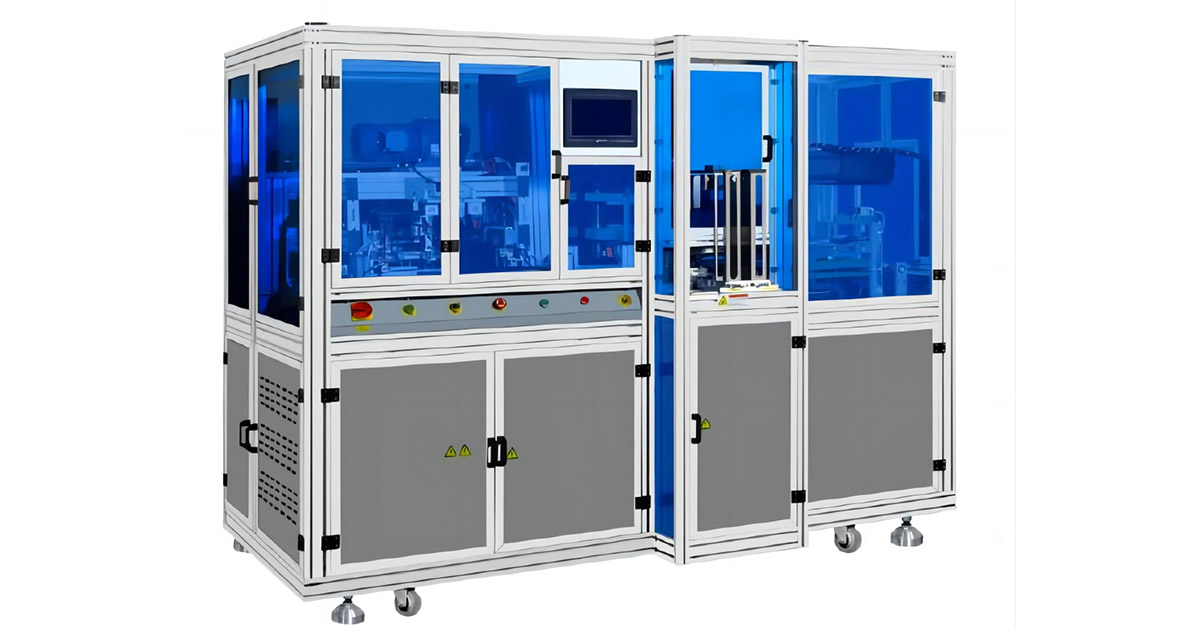

Transform your card manufacturing process with our cutting-edge Automatic Card Production Equipment, designed for high precision and efficiency. This comprehensive system integrates advanced technologies to automate every stage of card production, ensuring superior quality and reliability. Ideal for businesses with demanding production requirements, this machine is your solution for seamless and effective card manufacturing.

Auto PVC Sheet Loading:

Our machine is equipped with three automatic sheet collating feeding frames. Each frame utilizes a gear motor to facilitate smooth material loading and precise sheet separation. The innovative cylinder structure ensures accurate initial positioning of PVC sheets, allowing for seamless operation.

High-Precision UVW Correction Platform:

Each feeding frame is paired with a UVW correction platform, featuring a high-precision cross roller design. This platform works in tandem with a step motor to adjust the X and Y positioning of every PVC sheet, ensuring that all layers fit together perfectly during the collating process.

Advanced CCD Vision System:

The built-in CCD vision system employs sophisticated color code detection to accurately monitor material positioning. By comparing detected positions to preset values, the system corrects any deviations, enhancing the overall accuracy of the production process.

Material Handling with Precision:

Our machine includes a high-precision moving arm equipped with a vacuum suction board. This system efficiently transports materials from the feeding frame to the UVW correction platform, ensuring smooth and precise material handling throughout the operation.

Robust Sheet Collating & Conveying Platform:

The platform features two servo feeding clamps, designed to move materials from collating positions efficiently. With integrated vacuum devices, this system ensures that sheets remain in place even during the most rigorous production phases, eliminating the risk of misalignment.

Ultrasonic Welding Technology:

Beneath the third sheet collating platform, ultrasonic heads are installed to perform spot welding on collated sheets. This technology guarantees that all materials remain aligned, simplifying subsequent production steps and improving overall product integrity.

Effective Dust Removal System:

To maintain the highest quality standards, the machine incorporates a sticky dust roller and tear-off sticky paper for cleaning PVC sheets. This ensures that all materials are free from dust and contaminants before they undergo collating and laminating.

Roll Film Correction Structure:

Our machine features a specialized structure that separates the overlay tension and feeding rectification for roll film. This innovation ensures that overlays are applied neatly and accurately during the welding and melting processes.

Film Laminating Platform:

Equipped with two ultrasonic heads, the overlay laminating platform automatically engages in spot-welding and hot-melting processes as materials pass through. An overlay pulling clip secures the finished product, ensuring a tight seal and enhanced durability.

Film Cutting Platform:

The servo motor drives the finished, spot-welded material to the cutting platform, where an electric eye ensures precise alignment before cutting. This guarantees that the roll film is cut accurately, optimizing the production flow.

Our Automatic Card Production Equipment is designed to streamline your production process while maintaining the highest standards of quality. With its integrated systems, you can expect:

Elevate your card production with our advanced automatic card production machine. Experience unmatched quality and efficiency in every card produced, and meet your production goals with confidence!

Copyright © 2022-2024 LDT, inc. All rights reserved E-mail:[email protected]