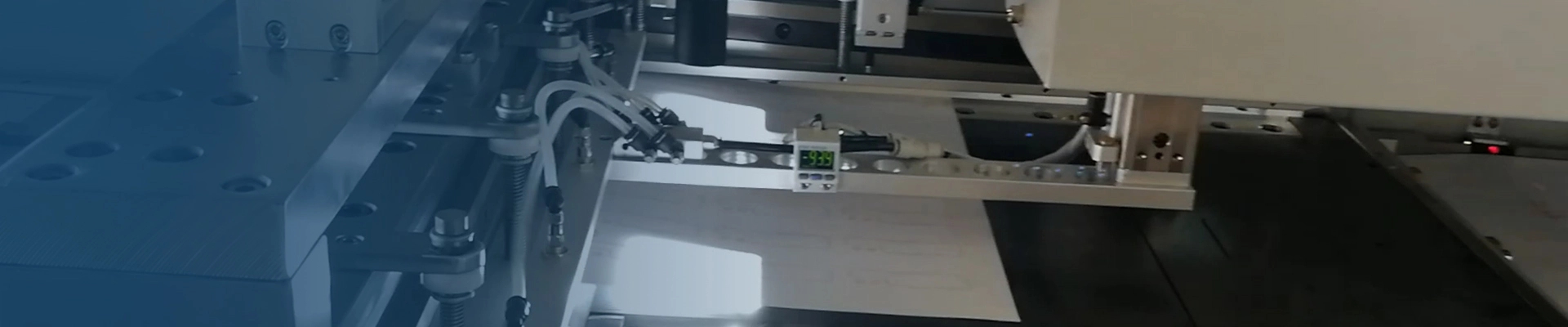

Model: LDT-APH-300

Auto Hole Punching Machine LDT-APH-300

Feature:

1. The machine is used for punching the chip holes on the sheet.

2. Adopting the touch screen, and operated by user-friendly interface.

3. Equipped with double cylinder punching pins which can be switched easily through the touch screen to realize the different punching sizes.

4. Servo motor drive the imported ball-screw finish positioning and feeding, the parameter of each punching point is adjustable,with high precision.

5. The whole process is simply and quickly.The feeding and punching methods include three-molds, four-molds and five-molds ,which can be selected flexibly.

Features:

1.Servo system ensures the accurate and reliable of INLAY sheet feeding,collecting and chip hole punching.

2.The feeding speed of the INLAY sheet and the chip hole position can be changed through modifying the parameter of the servo system on the touch screen.

3. With two different punching sizes to the same type chip. Each mold equipped with double cylinder punching pins which can be switched easily through the touch screen to realize the different punching sizes.

Machine Spec:

1.Power source: AC220V 50/60HZ 20A

2.Power: 0.6KW

3.Compress Air: 6 kg/cm2

4.Air Consumption:20L/min

5.Weight: About 300kg

6.Speed: 450sheet/hour

7.Dimension:L1650mm*W700*H1500

8.Control Method: Servo located + PLC

9.Operator:1 person

10.Material Specification:0.2~0.4mm PVC,PET...