Model:LDT-HA1024

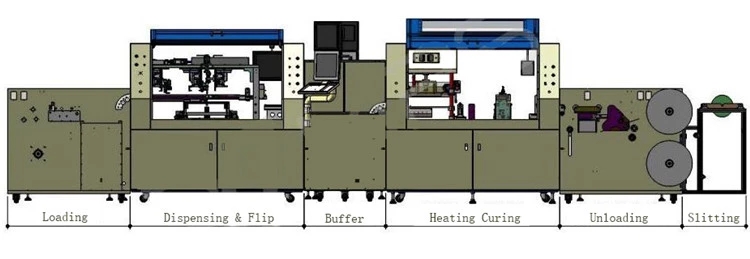

Our RFID Flip-Chip System is using Visual System to locate the chip and the antenna with the throughput in almost 99.5% yield. All processes are in one system platform which includes antenna web handling, epoxy jetting, flip chip, final curing, and testing. Available for all types of HF / UHF RFID Inlay

• Loading Module

• Dispensing Module

• Flip Chip Module

• Visual Module

• Wafer Module

• Buffer Module

• Heating Curing Module

• HF/UHF Testing Module

• Slitting Module

• Unloading Module

• Chip Backing Paper Module

ITEM | DESCRIPTION | QTY |

High Speed Camera | • Basler | • 1 set |

Servo Motor | • Panasonnic | • 33 sets |

Speed Motor | • JSCC | • 5 sets |

Touch Screen | • Weinview | • 2 sets |

Lead Screw | • KURODA | • 1 set |

MODEL | LDT-TTA10000 |

Dimensions | • 7300mm*1500mm*1560mm |

Power Supply | • 10KW AC 220V/50HZ |

Weight | • 4500KG |

Bonding Speed | • 8500 UPH (Related to antenna layout) |

Bonding Accuracy | • ±30μm |

Wafer Dimensions | • 8", 12" |

Chip Specification | • 0.4~2.0mm |

Compressed Air | • 0.45Mpa~0.6Mpa |

Vacuum Pressure | • -80Kpa~-100Kpa |

Material Bandwidth | • 100mm—370mm |

Bound Point Spacing | • CD>16mm MD>30mm |

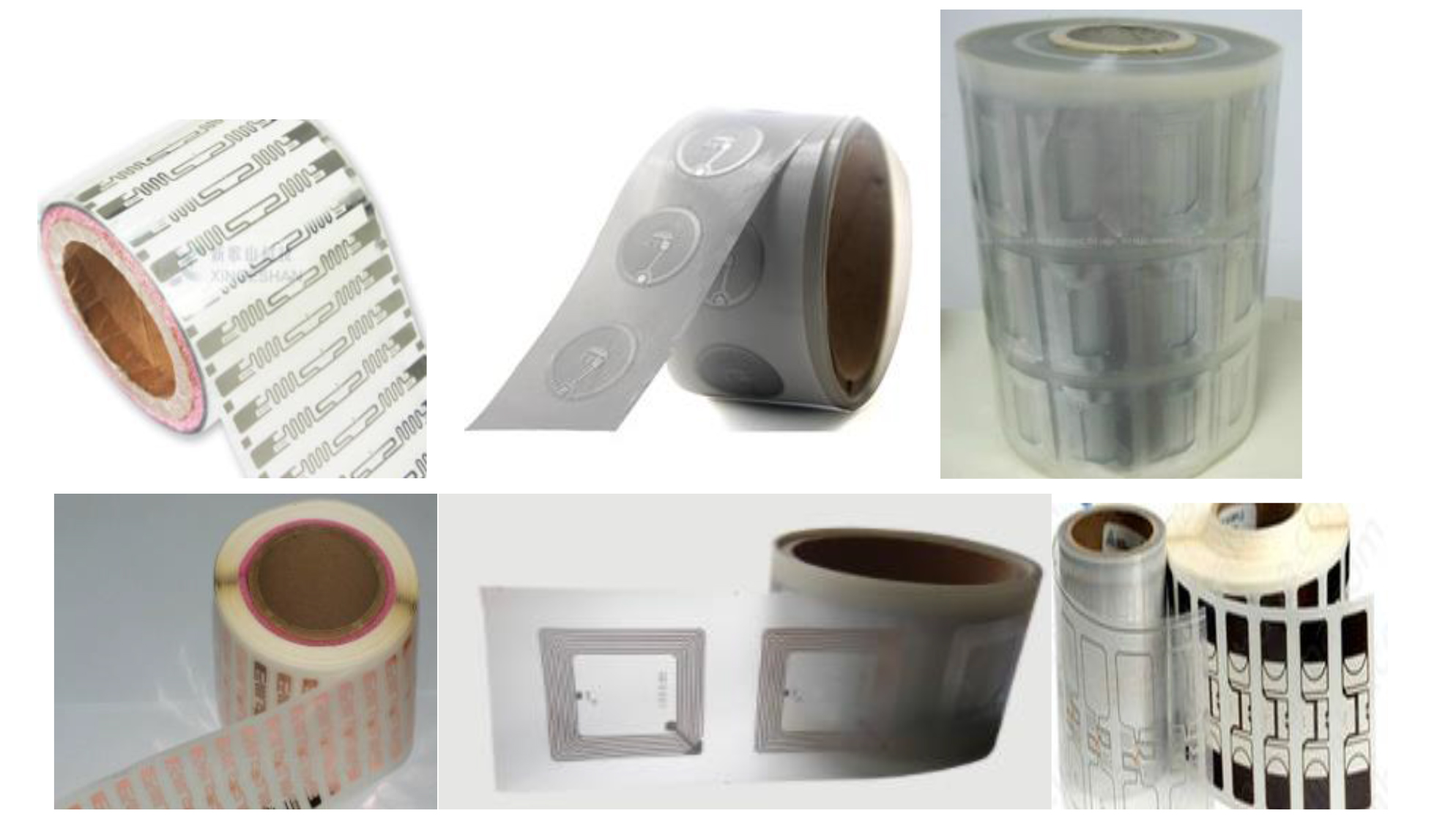

APPLICATIONS

Copyright © 2022-2025 LDT, inc. All rights reserved E-mail:[email protected]