Model:LDT-BTA2019A

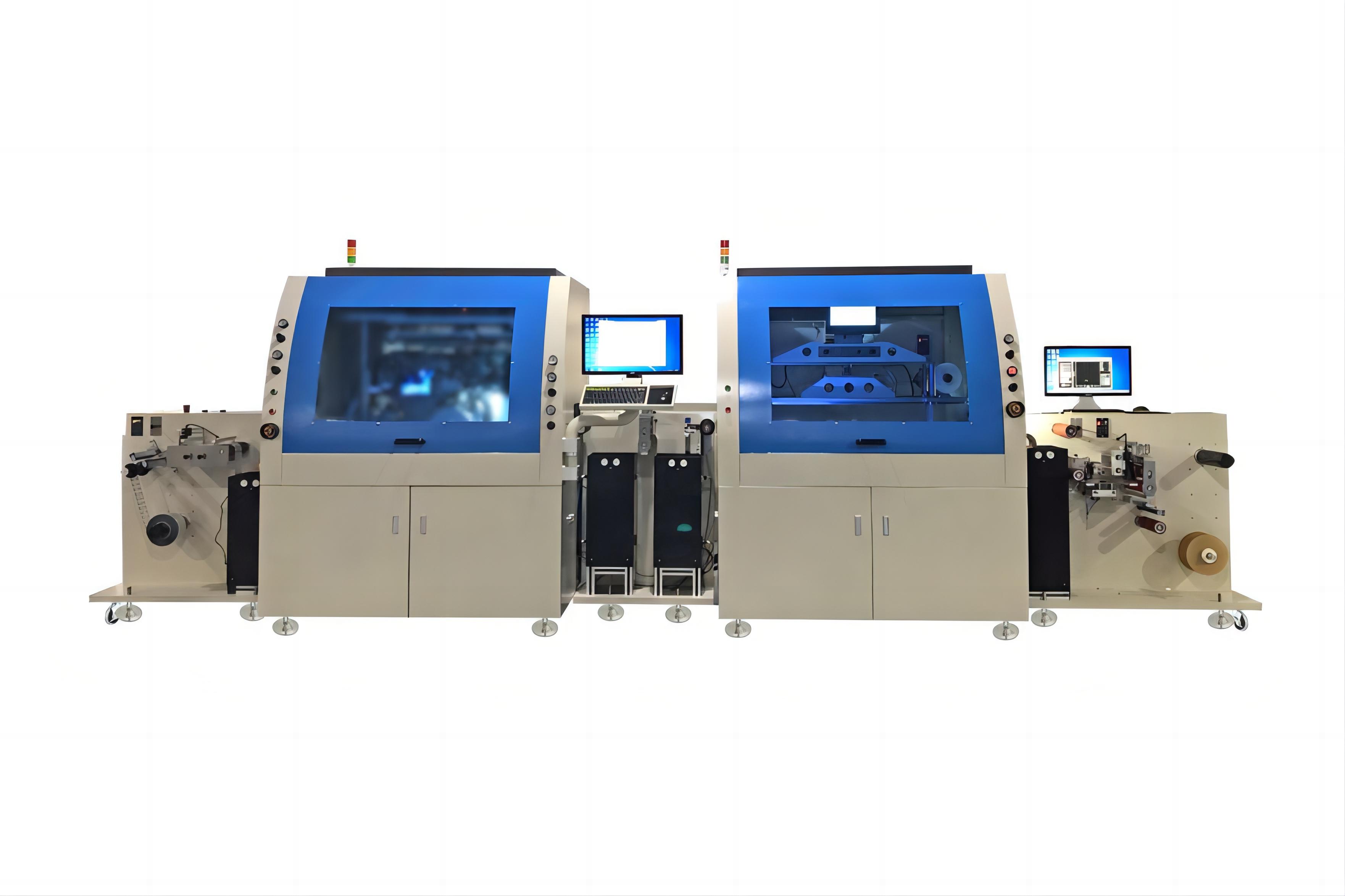

XJL-TTA20000 is the first domestically developed and innovative single-channel RFID production equipment. It has a number of invention patents and utility model patents which uses a high-precision visual motion system to accurately identify RFID chips and flexible antennas, positioning and high-speed precision actuators to achieve precise binding of microchips and antennas.

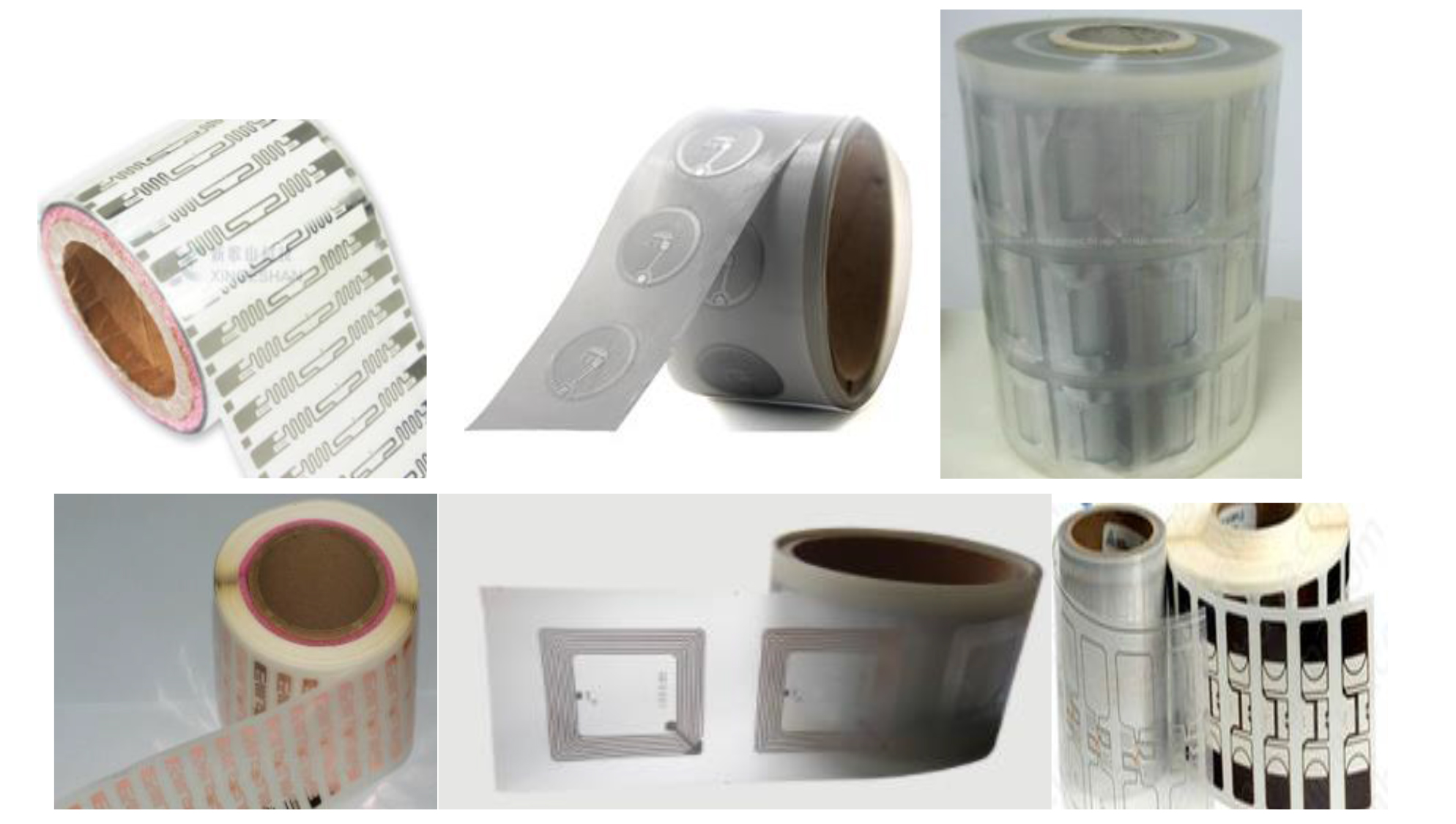

With the throughput in almost 99.5% yield, all of our processes are in one system platform which includes antenna web handling, epoxy jetting, flip chip, final curing, and testing. Available for all types of HF / UHF RFID Inlay

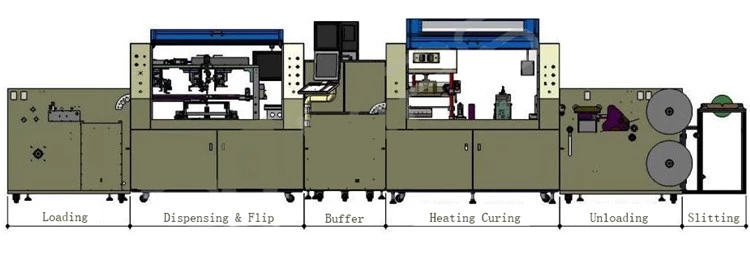

• Loading Module

• Dispensing Module

• Flip Chip Module

• Visual Module

• Wafer Module

• Buffer Module

• Heating Curing Module

• HF/UHF Testing Module

• Slitting Module

• Unloading Module

• Chip Backing Paper Module

MODEL | LDT-TTA20000 |

Dimensions | • 6100mm*1200mm*1800mm |

Power Supply | • 12KW AC 220V/50HZ/30mA |

Weight | • 3000KG |

Bonding Speed | • 16000 UPH (Related to antenna layout) |

Bonding Accuracy | • ±40μm |

Wafer Dimensions | • 8", 12" |

Chip Specification | • 0.3*0.3 – 1.0*1.0 |

Chip Thickness | • ≥100μm |

Wafer Expansion | • Φ240mm/Φ330m |

ACP Glue Process Mode | • Glue Spray |

Glue Dispense Accuracy | • ±40μm |

Dispensing Volume Control | • ±10% |

Compressed Air | • 0.4Mpa~0.6Mpa |

Vacuum Pressure | • -80Kpa~-100Kpa |

Material Bandwidth | • 30mm—150mm |

Bound Point Spacing | • CD>16mm |

Antenna Material Type | • PET, PP, Paper |

Hot Pressure Section | • 50g-400g |

Paper Thickness | • 80g-180g |

Hot Pressure Temperature | • 0°- 250° |

Pressure Control Section | • ±0.1N |

Hot Pressure Curving Quantity | • 56 group curving unit |

Temperature Control Accuracy | • ±5° |

On-line Detection Type | • UHF & HF |

Reject Mark Way | • Ink dot mark |

| • Yes | |

ID of Roll | • 76mm |

OD of Roll | • ≤400 |

Maximum Heating Power | • 7KW |

APPLICATIONS

Copyright © 2022-2025 LDT, inc. All rights reserved E-mail:[email protected]