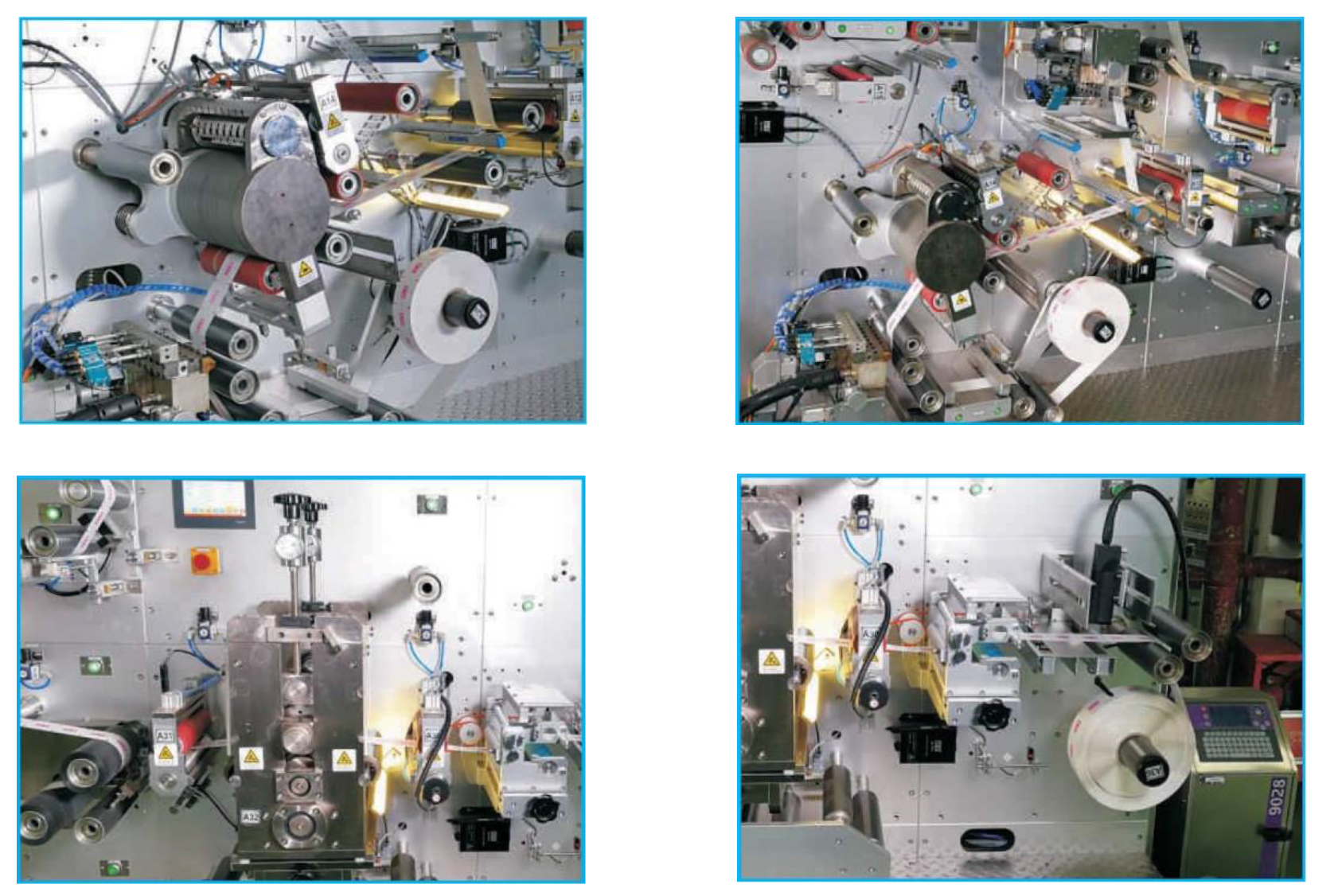

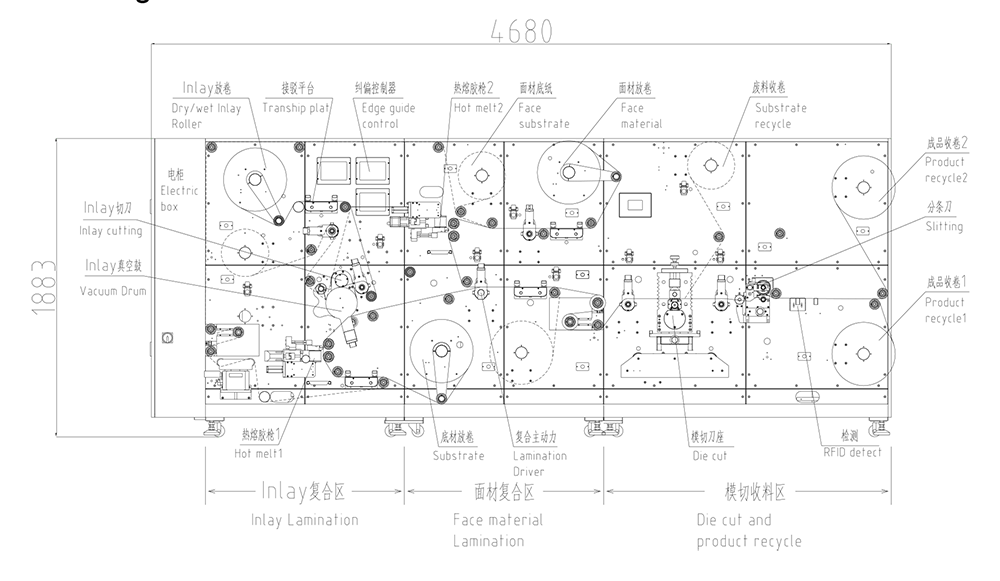

OVERVIEW

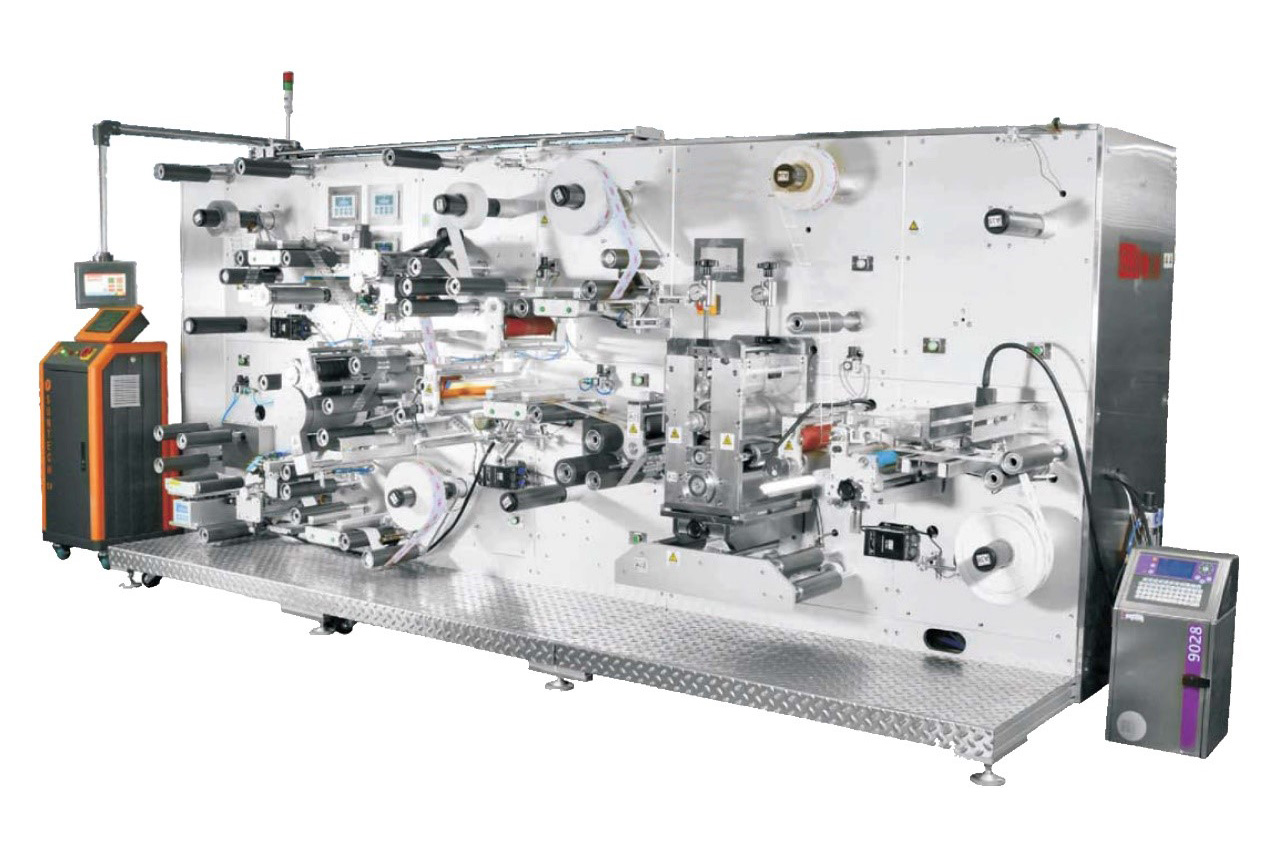

Label Automatic Lamination Machine is integrated with RFID inlay laminating, surface of RFID tag laminating which includes converting of pre die-cutting label and continuous label.

The speed of automatic laminating may reach to 60 meters per min. Assort with the special dry INLAY die-cutting module and hot melt glue mechanism, our machine is able to laminate dry & wet inlay label. Simultaneously if with high speed magnetic roller die-cutting module, we may help to implement the label after the process of die cutting and cards production.

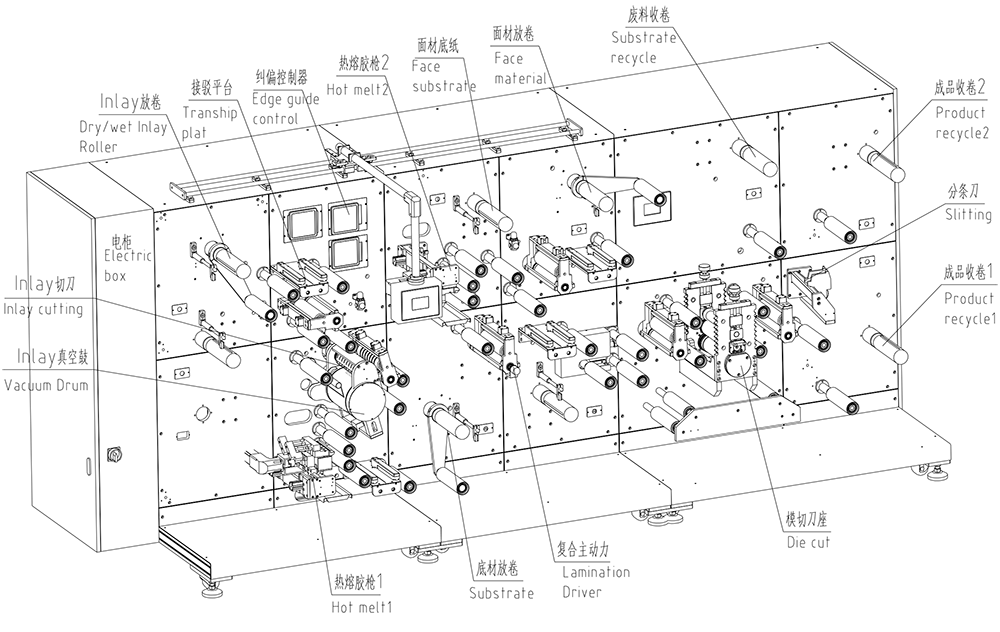

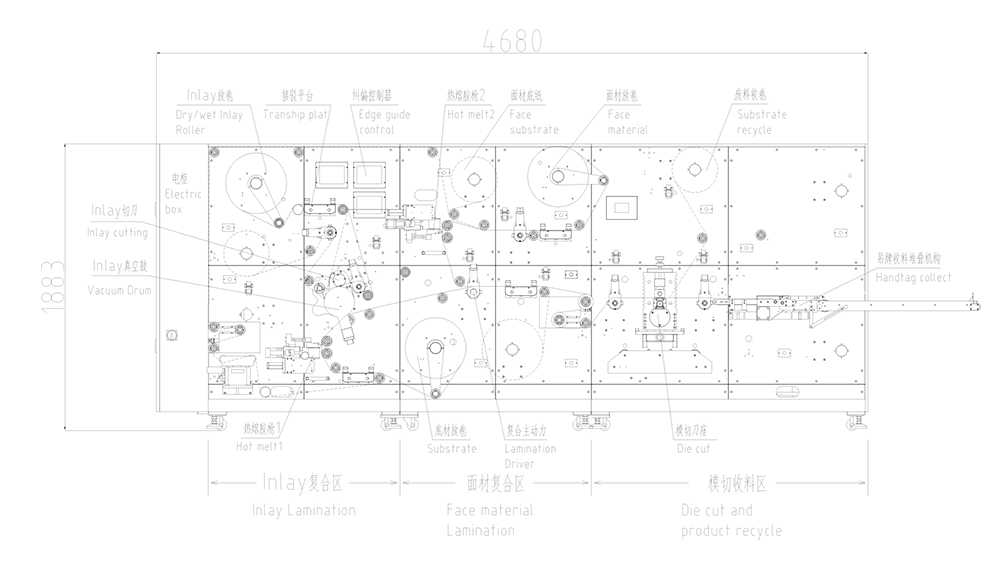

SYSTEM

FEATURES

• Dry inlay/wet inlay applied with inlay positioning cutting and vacuum drum institution. 3 sets high-speed rectify deviation Machine. 13 shaft servo system control.

• The main servo feeder institution.

• The finish paper is pre die-cutting by vacuum drum institution enable to have stabilized labeling.

• The ultromotivity constant tension institution of inlay label.

• The Label unwinding axial deviation to ensure stabilized label transfer.

• Specially install a non-stop lap changing device, making changing roll and paper receiving without stopping the machine become true.

• Automatically speed adjusted to track alignment.

• Lamination accuracy is±0.3mm (Subject to material printing accuracy, normally the general accuracy is in ±0.5mm).

SPARE PARTS

ITEM | DESCRIPTION | QTY | REMARK |

RFID Label Automatic Lamination Machine host | LDT-545 | 1 SET | |

Hot melt adhesive glue system | LDT-HT-303 (Servo Control) | 1 SET | |

Roller die cutting unit | LDT-U22A(Servo Control) | 1 SET | |

Conveyor for tag product | LDT-545 | 1 SET | |

RFID Detection system | UHF/HF testing system | 1 SET | |

NOK Inkjet | Imaje 9028 | 1 SET | Black mark for NG label |

SPECIFICATIONS

Production Speed | • Max.60M/Min(Subject to label material) |

Laminate Accuracy | • ±0.5mm(±0.3mm in condition of High precision material printing) |

Label Max. Width | • 190mm |

Label Max. Length | • 520mm(die-cut length) |

Label Max. Thickness | • Less 300g by single layer |

Label Inner Diameter | • φ76mm |

Label External Diameter | • Max. φ520mm |

Function | • RFID dry/wet Inlay, paper, fabric Laminating. |

Machine Size | • 4410*1600*1950(mm) |

Power | • 3 Phase 380V / 50-60Hz / 18KW |

Weight | • 4000Kg |

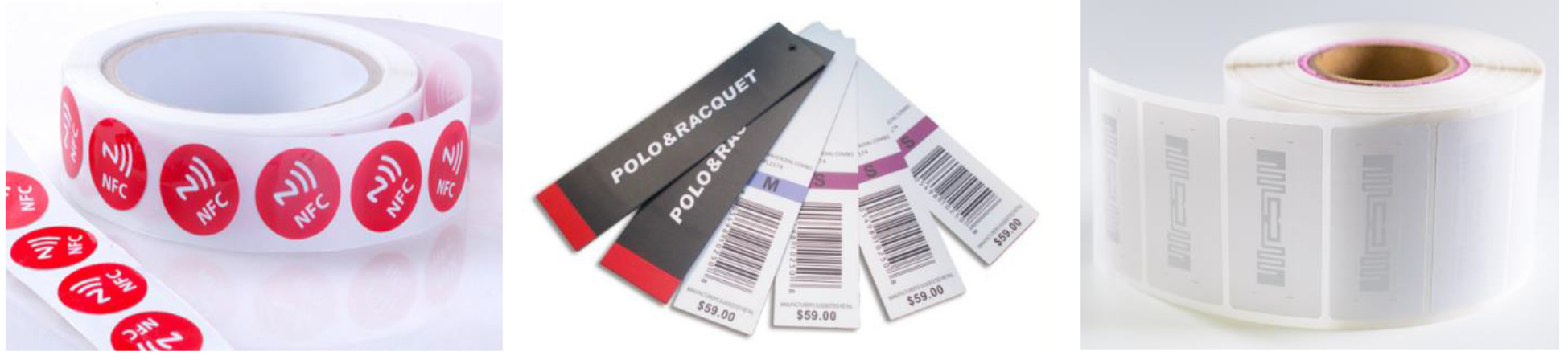

APPLICATION

• Ordinary paper of RFID lamination.

• Hand-tag RFID lamination.

• Care-label RFID lamination.

• Dry inlay & wet inlay lamination.

• Cutting function for dry inlay.

• Finish paper and body paper automatically alignment laminated.

• From the type of silicone oil body paper can be used as body paper.

• Double side adhesive label lamination.

• Standard adhesive label lamination: Label body paper & finish paper split – laminating inlay- Three layers label lamination.

• Dry inlay/wet inlay applied with inlay positioning cutting and vacuum drum institution. 3 sets high-speed rectify deviation Machine. 13 shaft servo system control.

• The main servo feeder institution.

• The finish paper is pre die-cutting by vacuum drum institution enable to have stabilized labeling.

• The ultromotivity constant tension institution of inlay label.

• The Label unwinding axial deviation to ensure stabilized label transfer.

• Specially install a non-stop lap changing device, making changing roll and paper receiving without stopping the machine become true.

• Automatically speed adjusted to track alignment.

• Lamination accuracy is±0.3mm (Subject to material printing accuracy, normally the general accuracy is in ±0.5mm).

Copyright © 2022-2025 LDT, inc. All rights reserved E-mail:[email protected]