OVERVIEW

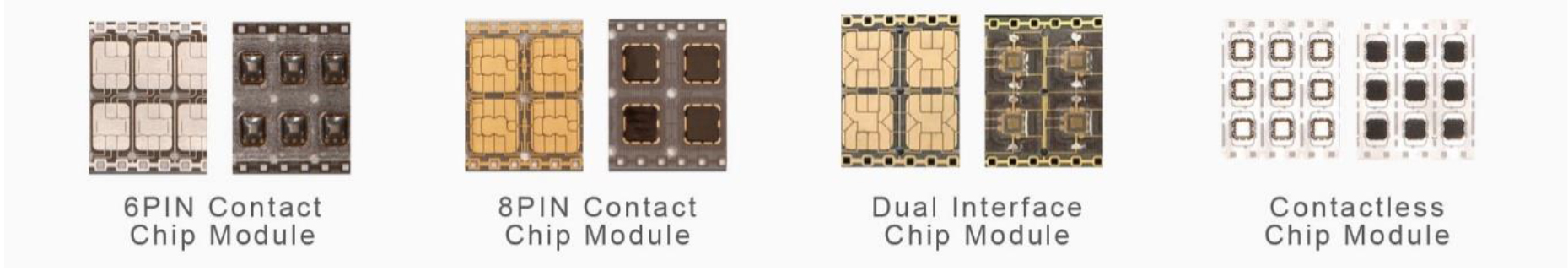

LDT-256T is an upgrade product designed for the increasing production requirement of chip encapsulation & testing factories and smart card manufacturers. The brand-new design enables operators to switch chips production between 6PIN and 8PIN within 60 seconds.

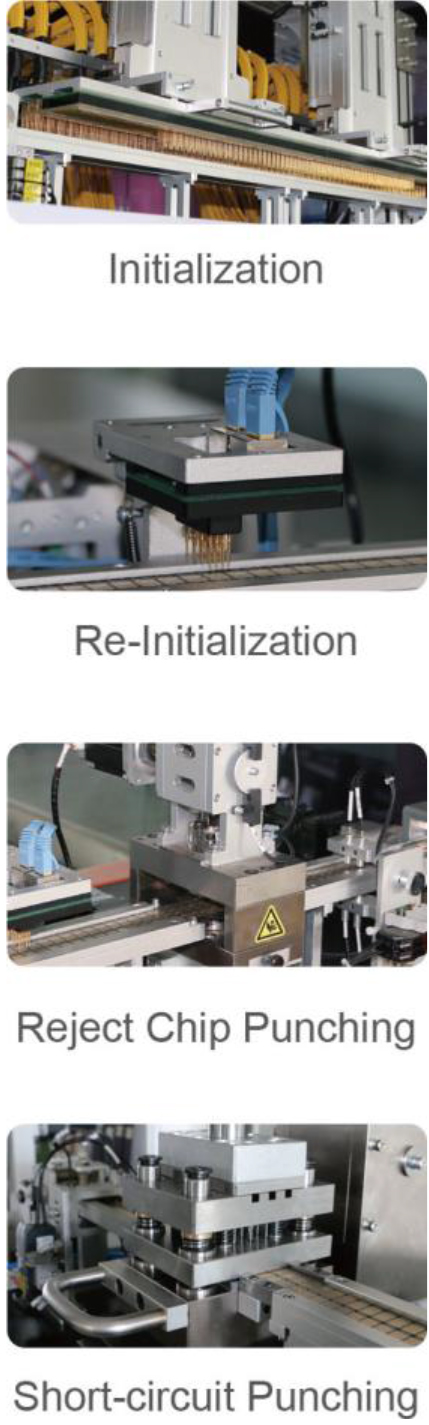

It integrates short-circuit punching, open and short test, chip initialization & pre-personalization as well as reject chip punching and marking. Modular design can meet your different production requirements and maximize decreasing your investment cost.

PTM-120B can be applied to contact/contactless and dual interface chip initialization, and also can be customized according to the demands for various chip production.

ADVANTAGES

• Unique Patented Technology

It only takes 60s to switch production tasks between 6PIN and 8PIN contact chip.

• High-performance Reader

The top Chinese industrial-class reader developed with open/short test function is stable and high cost-effective.

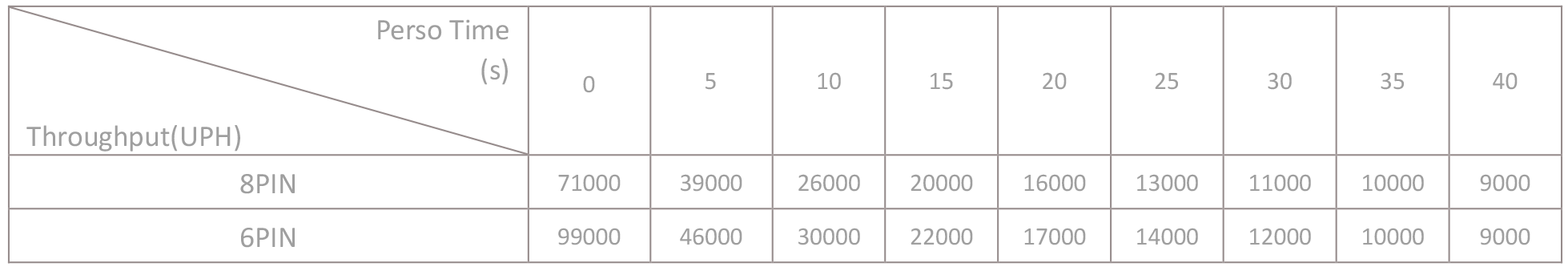

• 120Heads Ensure High Throughput

Max. throughput 99,000UPH for 6PIN chip;

Max. throughput 71,000UPH for 8PIN chip.

• Modular Design

Each module can work independently or be combined on demand.

• Unrestricted Workplace

Free of production site due to electric driving design without external air supply.

CONFIGURATIONS

Including short-circuit punching module | Excluding short-circuit punching module | |

Dimension | • 4750mm x 840mm x 1960mm | • 3800mm x 840mm x 1960mm |

Weight | • 800kg | • 650kg |

Power Supply | • 220V (-5% ~ +10%), 50Hz, 4KW | • 220V (-5% ~ +10%), 50Hz, 2KW |

Maximum Throughput | • 60,000UPH | • 99,000UPH (6PIN) |

Short-circuit Punching Throughput | • Max. throughput 60,000UPH(14 chips/punch) | |

Noise | • <50dB | |

Operation Temperature | • 23℃ ± 3℃ | |

Operation Humidity | • 50 ± 10% | |

Chip Module Specification | • M2 and M3 | |

Communication Interface | • Ethernet | |

Copyright © 2022-2025 LDT, inc. All rights reserved E-mail:[email protected]